Next generation logistics

Almost 50 years ago, Häfele established its logistics center on the Wolfsberg industrial estate just outside Nagold. The company is now investing in expanding the site as the first step along the next half century of successful logistics services. io has been working with Häfele for more than three years now, helping to optimize logistics, expand the building structures and the related IT landscape, and shape Häfele’s European strategy.

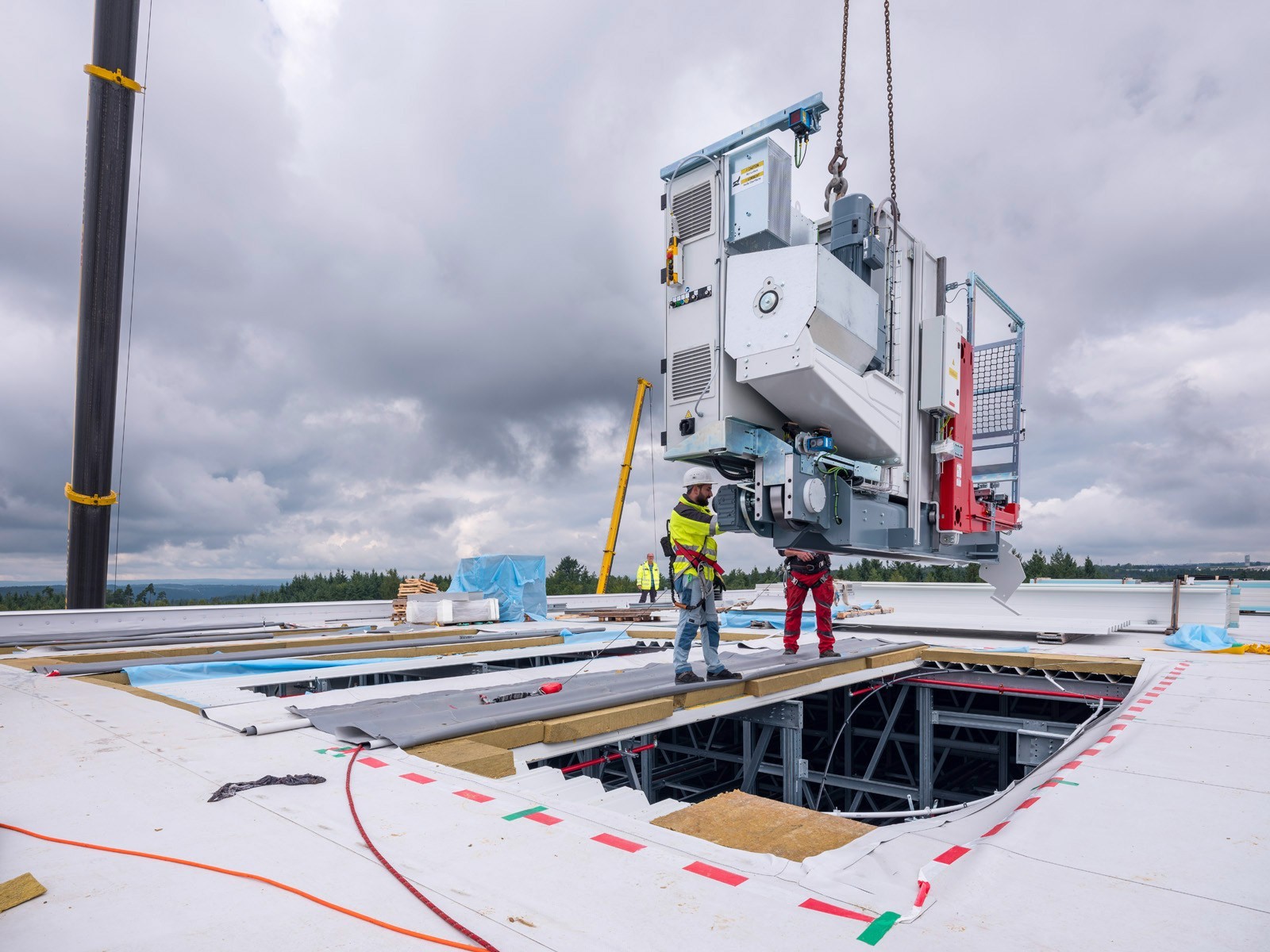

The construction of the new high-bay warehouse and the associated plant expansion in Nagold mark the start of expanding and modernizing the existing logistics facilities.

Supported by io as lead consultant, Häfele is expanding the plant by approx. 15,000 storage spaces. Around 6,000 shipments currently leave the warehouse every day.

Following the successful launch of the site in northern Germany, we are now expanding the warehouse capacities and the goods receiving area in Nagold. We are proud to have reached this further milestone together with io.

Key Facts

Client

Häfele GmbH & Co. KG, headquartered in Nagold, south-west Germany, is a leading international specialist in furniture fitting technologies, electronic locking systems and LED lights. Founded in 1923, the family business today serves clients from over 150 countries worldwide, developing and producing its products in Germany and Hungary.

The challenge

New warehouse buildings and process design needed to be integrated into Häfele’s existing building and logistics structures.

The modernization had to be carried out during ongoing operations, without affecting the day-to-day work.

Solution

- Successive conversion of logistics processes

- Step-by-step expansion of warehouse and conveyor technology and the picking workstations

- High-bay warehouse expansion to shorten walking distances and make workplaces more ergonomic

Successive conversion of logistics processes

All work will be carried out during ongoing operations without affecting Häfele’s ability to deliver, which in turn is ensured by detailed migration planning.

Simultaneously to expanding the logistics capacities, the first step is being taken towards gradually converting the logistics processes. Goods-to-person picking, for example, will be standard in the warehouse in future. The planned high-bay warehouse with around 15,000 storage spaces and seven aisles will mean shorter walking distances and more ergonomic workplaces.

Commissioning is scheduled for the beginning of 2022.

The planned high-bay warehouse with around 15,000 storage spaces and seven aisles.