Systematic and sustainable planning

In the case at hand, a new production line was to be added at a factory for shading systems, requiring an annex on a neighbouring plot of land. The white paper illustrates how value stream mapping was used to reveal the weak points in the existing production flows, and how improvement opportunities were developed in a value stream design workshop.

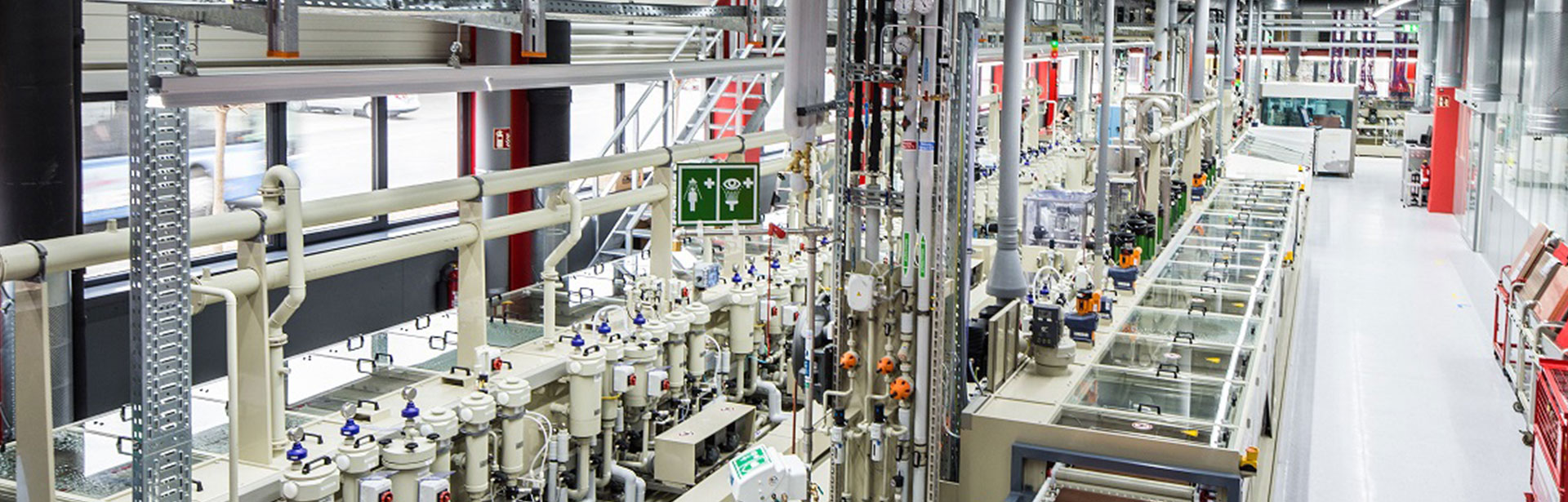

The resulting layout for a holistic production system was subsequently implemented at the new site. Ensuing synergy effects have led to reduced handling and transport costs and significantly shorter throughput times.

Request our white paper now!

A building expansion is required to meet increasing demand in a make-to-order production system with strong seasonal fluctuations. How can this be planned in a systematic and sustainable way?