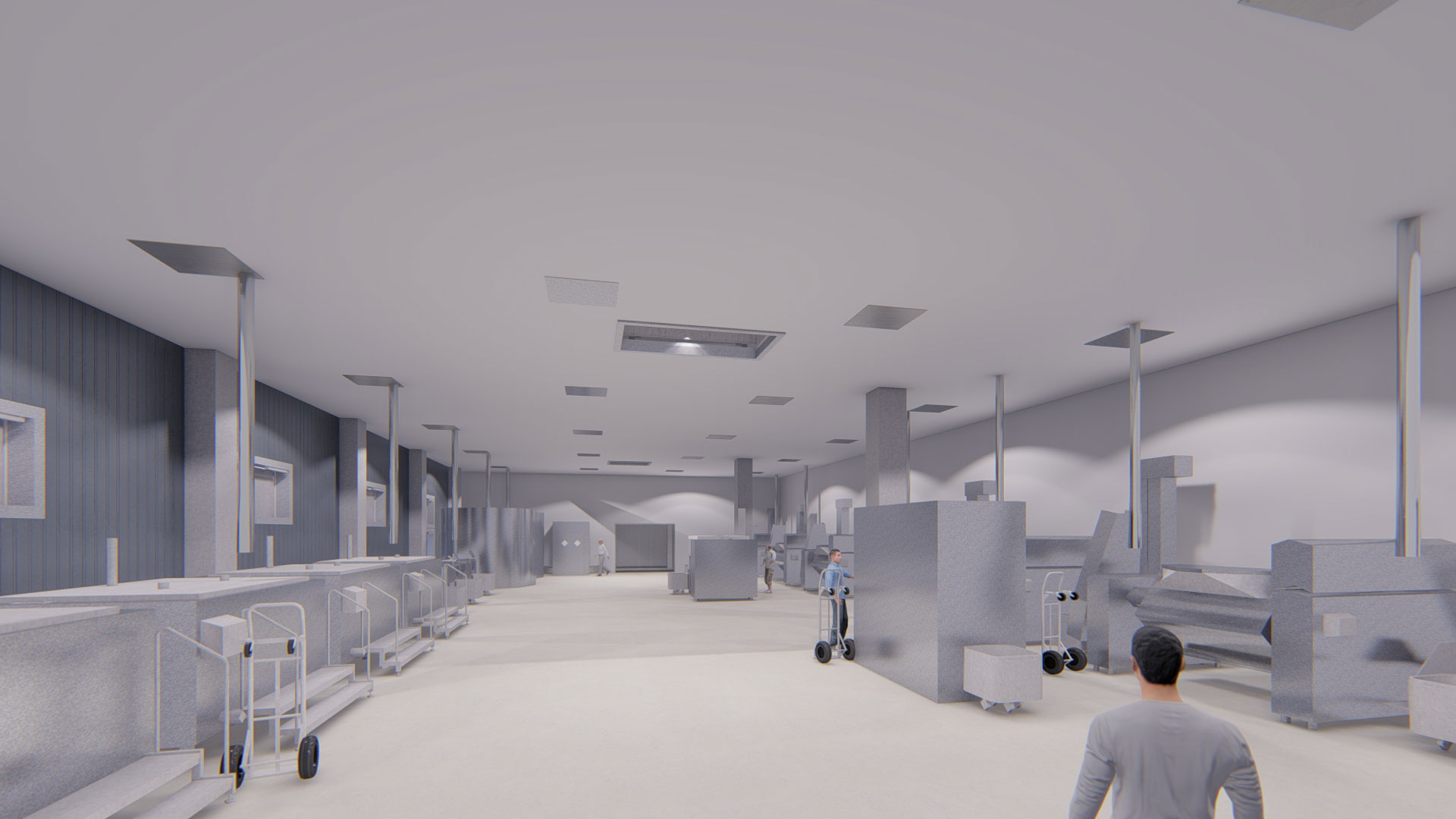

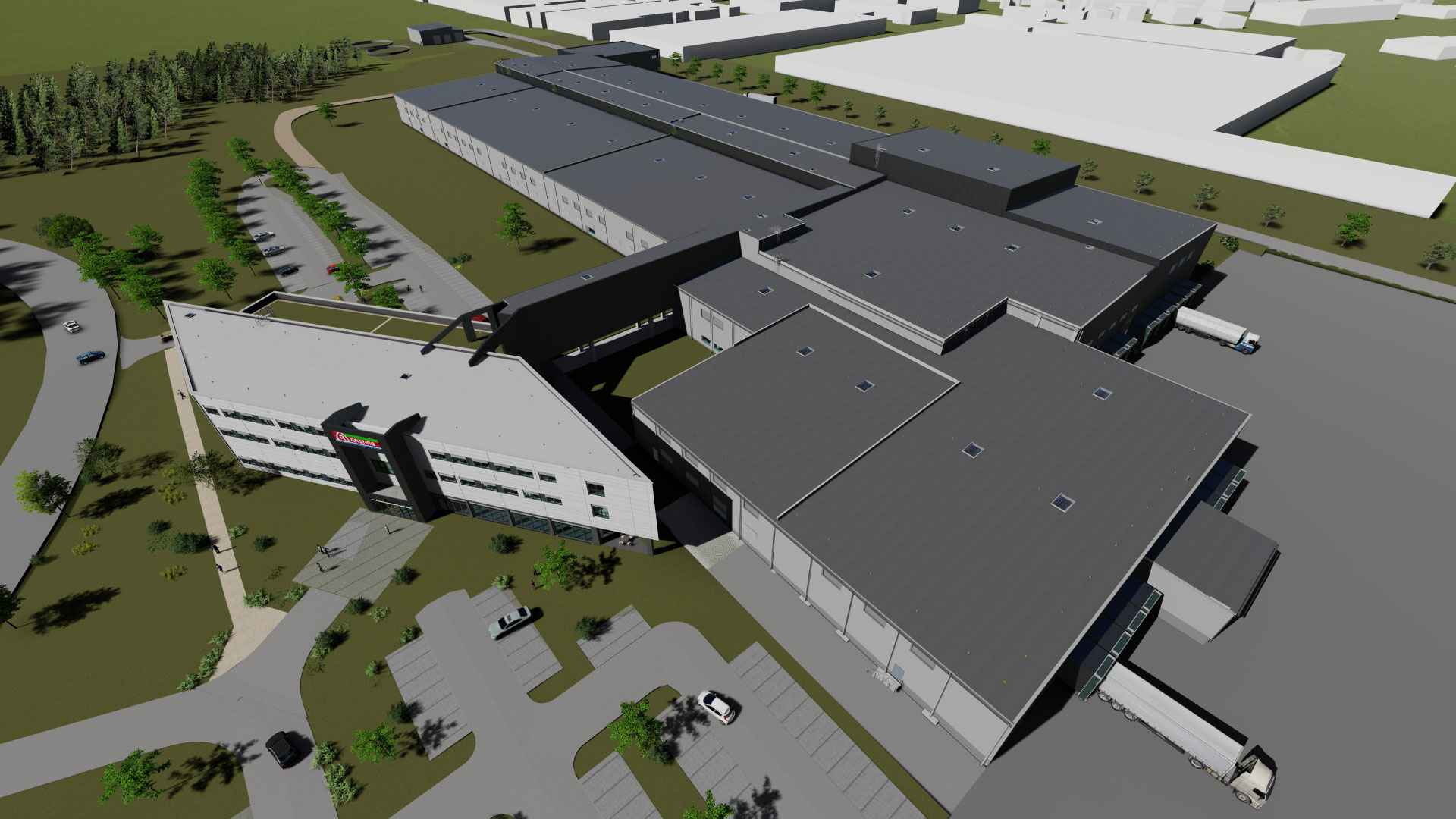

New building planned on a greenfield site

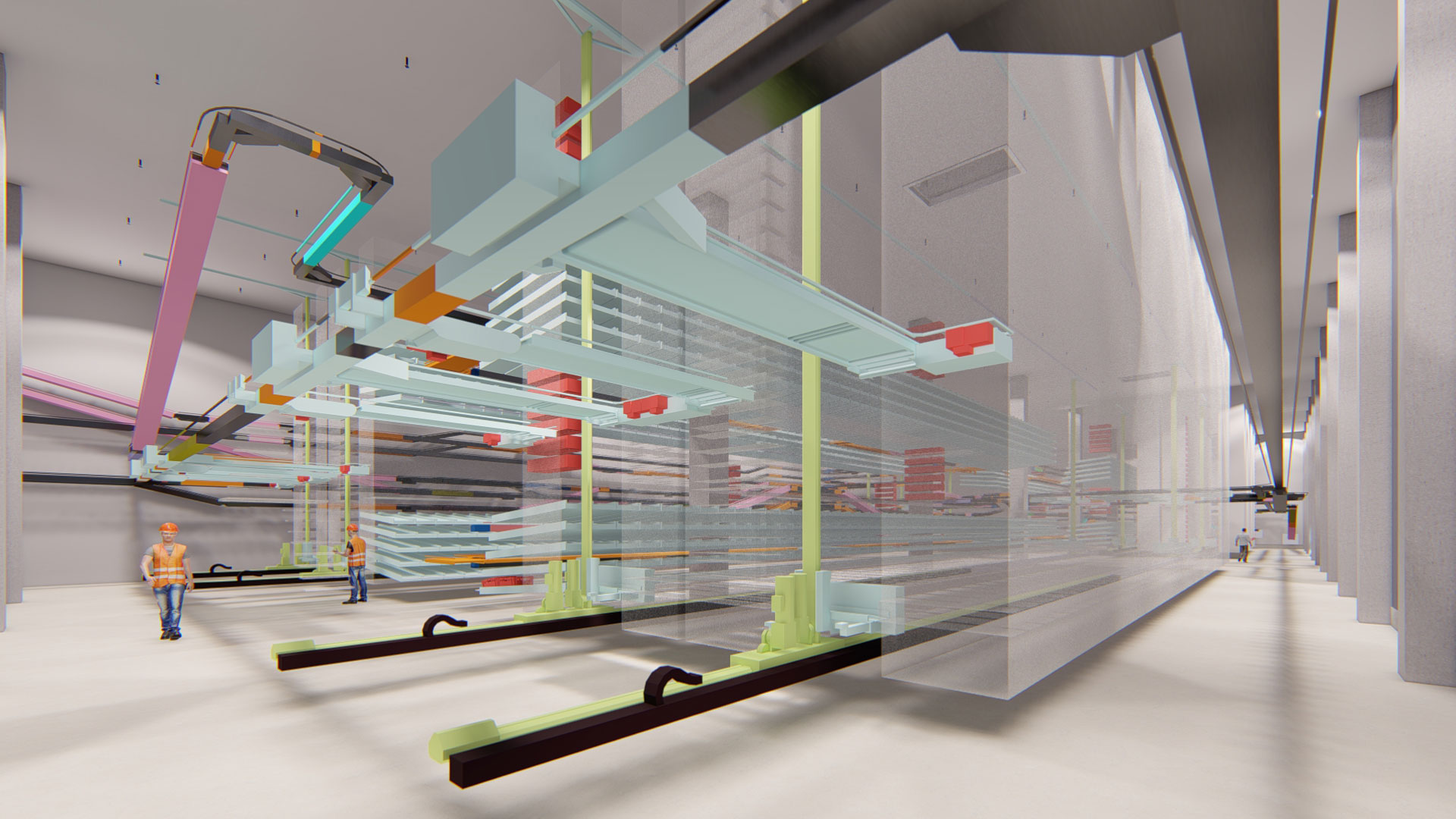

Rasting and io carried out initial preliminary planning and site evaluation studies back in 2017. After the decision was made to build a new building in Meckenheim, a team from factory design, TBE, architecture and project management began working with Rasting to develop the concept from the initial ideas through to a complete design. The planning team’s resulting design meets Rasting’s high flexibility and hygiene standards in production. At the same time, a separate technical level was offered to meet their desire for self-sufficient TBE.

io offers an impressively holistic approach. Process and building design are seamlessly coordinated to create a well-designed overall result.

io is also supporting Rasting in coordinating the urban land use planning procedures, running parallel to the planning process, and supervising the necessary German Law on Emission Control (BImSchG) requirements. In addition to the approval process, io has been commissioned to carry out further tendering, awarding and implementation support.

Key Facts

Client

Fleischhof Rasting GmbH is a subsidiary of EDEKA Rhein-Ruhr Stiftung and operates plants in Essen and Meckenheim with a total workforce of around 1,000. As a result of its steady growth, Rasting is working with io to plan a new building to produce its meat and sausage range, as well as other ready meals and delicatessen products. The land earmarked for the new building is next to the existing plant in Meckenheim.

The challenge

- Plan a factory that can flexibly adapt to Rasting’s existing and growing product range, with the option to expand production for potential new product segments

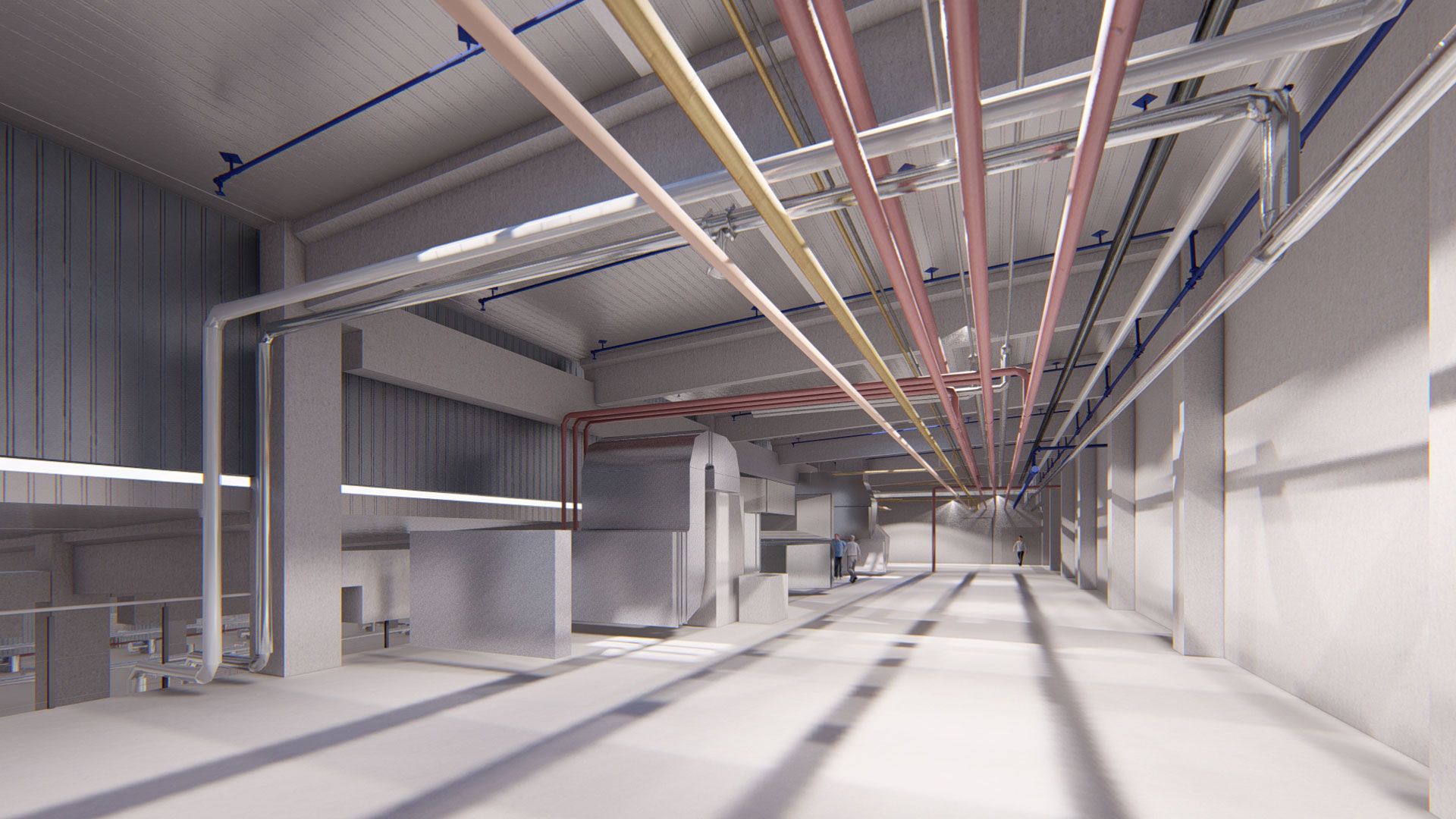

- Integrate an efficient, draft-free climate control system for the wellbeing of employees

- Design an energy-efficient and sustainable building services system, with the aim of creating the world’s first practically CO2-neutral factory for meat and sausage products

Solution

- Design a factory layout that facilitates future structural expansions, taking into account the internal process arrangement and site conditions

- Integrate ventilation and air-conditioning systems that introduce cold air into the production rooms indirectly and without causing drafts, while simultaneously regulating the indoor climate (temperature and humidity)

- Incorporate a woodchip power plant adjacent to the production building, making the site’s energy supply independent of fossil fuels